- Builder

- American Car & Foundry Co.

- Description

- High Voltage "Gibbs" subway car

- Secondary Use

- None

- Type

- Rapid Transit Cars

- Year

- 1904

- Retired from Service

- 1956

- Acquired by the Museum

- 1956

- Note

- No. 3352 is stored indoors and is undergoing restoration work.

- Fund

- 700

- Sponsor/Manager

- James Tebbetts

Interborough Rapid Transit 3352

From New York, New York

History

The Interborough Rapid Transit Company was organized in 1902 by August Belmont, Jr. to build New York City’s first subway. It also leased New York’s Metropolitan Elevated system. When the subway was being designed, the issue of safety was important, since most of the line would be in tunnels. Although the initial equipment for the line would be of composite steel-wood construction, the company embarked on a program to develop an all-steel car which would be both fire and collision resistant. Engineers had previously believed that a car would come apart under the stresses of vehicle operation unless it contained at least some wood to absorb shocks. At the time, the Pennsylvania Railroad was planning to build Pennsylvania Station in New York City. PRR President Alexander Cassatt also wanted the safety of an all-steel car for the tunnels needed to reach the new station which was to open in 1910. Cassatt made an offer to August Belmont Jr., President of the IRT, to build a sample steel car for the subway. After the IRT tested this prototype all-steel car designed by Pennsylvania Railroad Mechanical Engineer George Gibbs, it ordered 300 similar production cars from American Car & Foundry (ACF). These cars, Nos. 3350-3649, were termed High-Voltage (Hi-V) “Gibbs” cars and came in 1904-05. ACF built No. 3352 in June 1904, and the IRT fitted out the car in August 1904. The IRT subway opened on October 27, 1904, and No. 3352 entered service a few days later on October 30, 1904. The steel cars’ performance immediately rendered all wood framed vehicles obsolete. The PRR and other railroads then began building all-steel cars.

On the night of December 4, 1907, No. 3352 was the lead car in an empty, stationary train. Another train, also with no passengers, moving at 30 to 40 m.p.h., collided with No. 3352's train. Because of No. 3352's steel anti-climbers, it sustained only minor damage. Other cars on both trains were wood-steel composite cars without anti-climbers. These cars telescoped in the collision and suffered serious damage. This incident helped establish the safety benefits of all-steel construction and the use of steel anti-climbers.

The IRT’s Hi-V cars were similar to the company’s elevated cars with doors at the ends and 16 transverse seats at the center of the body. In 1910-12, the IRT added pneumatically operated center doors to improve passenger flow. The end doors remained manually operated by a conductor. The Hi-V cars used 600 DC voltage from the third rail for the motorman’s propulsion control while IRT cars built beginning in 1915, called “Low-Voltage cars,” used 32 volts from a battery for the motorman’s controller.

In 1940, the City of New York acquired Interborough Rapid Transit and operated the IRT lines as well as the BMT and IND systems under the New York City Board of Transportation. In 1953, the city formed the New York City Transportation Authority to operate the subways. The NYCTA ordered new cars to replace its oldest equipment. This program included the R-22 cars, such as No. 7371 now also at Seashore, to operate on the IRT lines and replace the Hi-V cars. No. 3352 ran in daily service for over a half a century and had to be called in off a regular train in 1956 to be sent to Maine.

In 1956, the New York City Board of Estimate passed a resolution to sell former Brooklyn Rapid Transit #4547 and a Hi-V car to Seashore for $1 each. Seashore selected No. 3352 for preservation as it was the oldest Hi-V car remaining at the time. During the 1960s, Seashore began restoration of No. 3352, rebuilding its body without the center door. In order to operate the car on museum trackage, Seashore installed trolley poles. Although exterior restoration is largely complete, significant interior work remains to be accomplished. No. 3352 is the only surviving car from the production run of the world’s first all-steel vehicles and is the world’s oldest existing all-steel railcar. As such, former Seashore Historian Ben Minnich called this car the most historically significant car in the Seashore collection.

Technical Information

- Seats: 52

- Control: M (C-18A)

- Brakes: AMRE

- Compressor: D-2-F

Trucks

- Number: 2

- Manufacturer: Baldwin

- Model: MCB

Motor

- Number: 2

- Manufacturer: General Electric

- Model: 69B

Weight and Dimensions

- Length: 51’ 2.00"

- Width: 8’ 10.00"

- Height: 12’ 0.00"

- Weight: 79200 lbs.

Additional Images

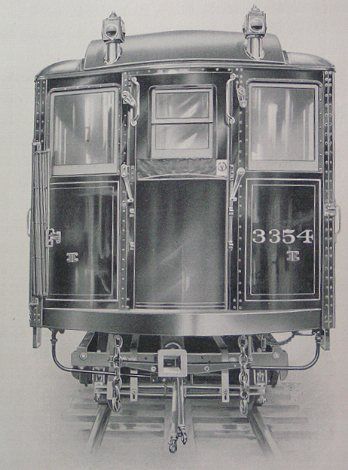

1903 drawing of end of car from wikipedia (public domain)

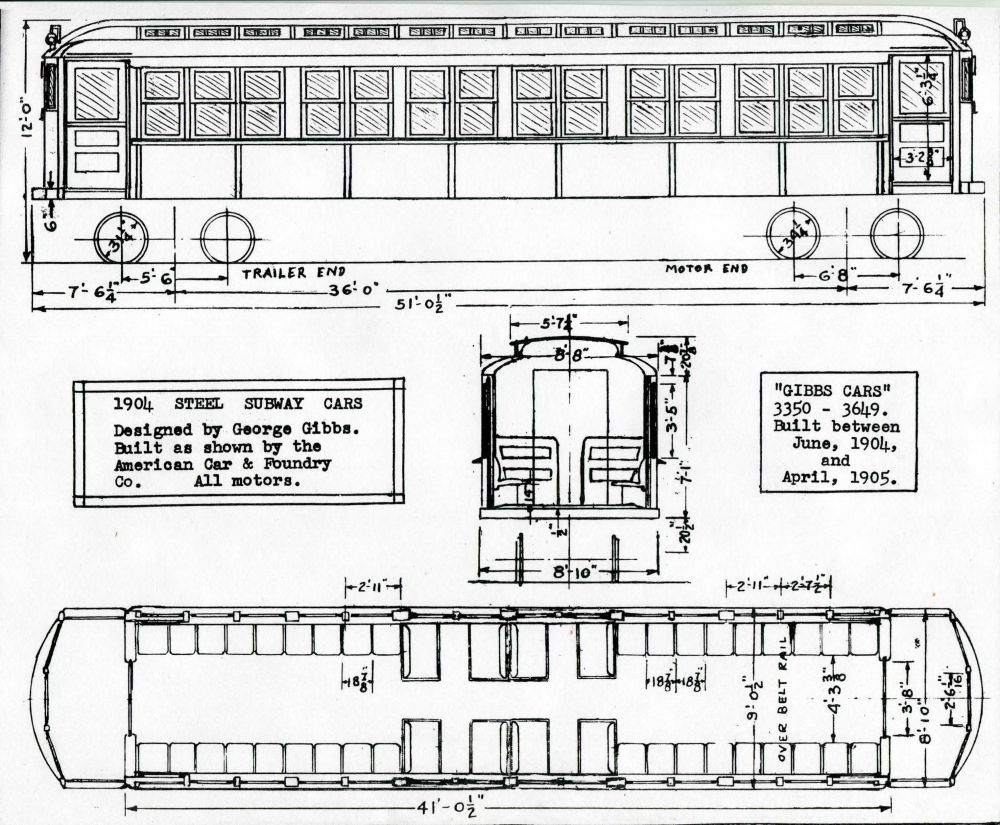

Roger Arca drawing of car 3352 dated 1904

James Tebbetts on 10/15/2020

© 1998 - 2025 New England Electric Railway Historical Society. All Rights Reserved.